Bintan, Riau Islands — PT Pertamina Hulu Energi Offshore North West Java (PHE ONWJ) has embarked on a new chapter in maintaining national energy security through the strategic OO-OX Project. A key milestone in this project is the successful fabrication and delivery of the 530-metric-ton OOA Platform Topside, a product of PT Meitech Eka Bintan, a subsidiary of PT Meindo Elang Indah.

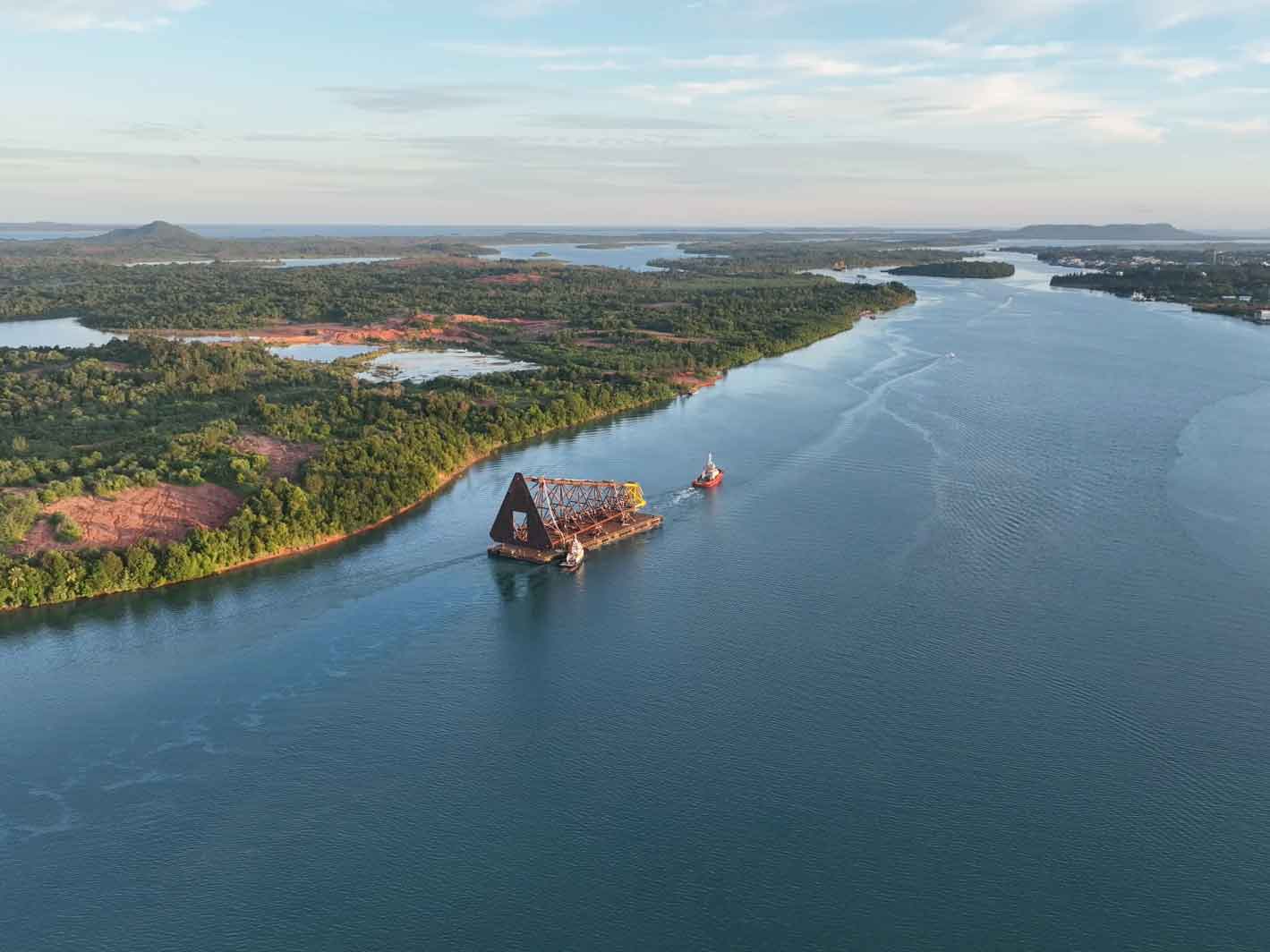

The fabrication process was carried out at the Meitech Eka Bintan yard facility on Bintan Island, Riau Islands, and was officially dispatched (sailaway) on Tuesday, June 24, 2025, by sea to its installation site in the waters off the northern coast of West Java.

From First Cut to Sailaway

The OO-OX Project commenced with the First Cut Steel ceremony, held directly at the project site on November 6, 2024. This moment symbolized the start of physical work for the construction of the new platform, which will enhance PHE ONWJ's offshore oil and gas production facilities.

Following the completion of the engineering and procurement phases, the physical fabrication of the OOA Platform Topside began at the Meitech Eka Bintan yard in early November 2024.

A series of critical tasks were executed structurally, including:

- Engineering & Design Finalization

Intensive collaboration between the Meitech and PHE ONWJ engineering teams ensured that all specifications and design details met national and international oil and gas standards. - Material Procurement & Steel Cutting

Oil and gas certified steel materials were processed through precision cutting at the Meitech yard, marking the beginning of the topside structure fabrication process. - Structure Assembly & Welding

The entire steel structure was assembled and welded by an experienced workforce, with strict Non-Destructive Test (NDT) controls to ensure the strength and safety of the connections. - Piping, Electrical & Mechanical Installation

The installation of piping, electrical, instrumentation, and mechanical equipment ran concurrently with structural work to maintain schedule efficiency. - Offshore Grade Painting & Coating

The topside was coated with heavy-duty protection resistant to corrosion and the extreme offshore environment, ensuring the structure's durability in the Java Sea. - Inspection & Pre-Commissioning

All work underwent rigorous inspection, pre-commissioning tests, and certification for readiness before sailaway.

Sailaway to the Java Sea, June 24, 2025

After the entire fabrication process was completed on schedule, the 530-metric-ton OOA Platform Topside was dispatched from the Meitech Yard port on Bintan Island on Tuesday, June 24, 2025. The shipment was conducted by sea using a heavy transport vessel, heading towards the waters off the northern coast of West Java.

Upon arrival at the offshore location, this topside will be installed on top of a pre-prepared platform jacket, completing PHE ONWJ's oil and gas production facilities as part of the OO-OX Project development.

Meitech Eka Bintan's Commitment to the National Offshore Industry

The successful fabrication and sailaway of the OO-OX Project topside is a testament to Meitech Eka Bintan's capacity as a national-scale offshore fabrication service provider. This project also represents Meitech's active contribution to supporting the national energy security program.

"We are proud to be part of this important project. This achievement is a tangible manifestation of Meitech Eka Bintan's commitment to continuously deliver high-quality offshore fabrication solutions for Indonesia's oil and gas industry" stated the management of Meitech Eka Bintan.

Positive Impact for the Region and Local Workforce

Throughout the fabrication process, this project has absorbed local labor from Bintan and its surrounding areas, while also empowering supporting contractors in the Riau Islands. This has created a multiplier effect on economic activity and the development of local workforce competencies.